TREATMENT SOLUTIONS UTILIZED:

- StormFilter™ 26 x 69cm in a StormFilter™ Vault(Perlite Cartridges)

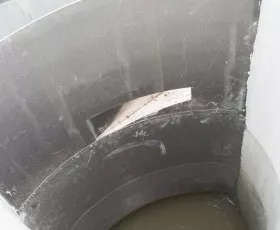

- Cascade Separator

PROJECT OVERVIEW:

Humes Pipeline Systems in Te Rapa, Hamilton, required a stormwater treatment solution to meet council regulations. The site’s stormwater runoff, primarily from a metaled yard, was being discharged into a nearby creek, necessitating a robust system to handle heavy sediment loads and prevent cross-contamination from adjacent industrial sites.

Stormwater360 was selected to design a low-maintenance treatment train, addressing sediment reduction, hydrocarbon capture, and external contamination control.

- Heavy Sediment Load: Runoff from the metalled yard produced significant sediment, requiring an effective system to handle these loads.

- Adjacent Industrial Sites: The design needed to prevent cross-contamination from neighbouring properties.

- Regulatory Compliance: The system had to meet council requirements, particularly for Total Suspended Solids (TSS) reduction.

Stormwater360 designed a comprehensive treatment train that included:

- Deep and Wide Sumps: Strategically placed to capture the heavy sediment load before stormwater enters the primary treatment system.

- Cascade CS4 (Gross Pollutant Trap): Installed upstream of the StormFilter™, the Cascade CS4 captures hydrocarbons, litter, and debris, removing 50% of TSS in pre-treatment, and reducing the strain on the downstream system.

- StormFilter™ with Perlite Cartridges: This final stage of treatment targets fine sediments and pollutants, achieving a minimum of 75% TSS removal before discharge into the creek.

This design ensured compliance with local water quality regulations and protected the site from potential cross-contamination.

TREATMENT OVERVIEW:

- TSS Reduction: The system is designed to remove at least 75% of TSS, reducing sediment pollution in the creek.

- Hydrocarbons, Litter, and Debris: The Cascade CS4 captures these pollutants before they can enter the final filtration system.

- Cross-contamination: The treatment train prevents pollutants from neighbouring sites from affecting stormwater quality at the Humes facility.

MAINTENANCE:

Installed in late 2022, the system underwent its first maintenance in June 2024. Stormwater360’s inspect-to-maintain service ensures the system remains fully functional with minimal maintenance required between service intervals.

CONCLUSION:

The retrofit stormwater treatment train at Humes Pipeline Systems' Te Rapa plant effectively addresses the challenges of high sediment loads and potential cross-contamination from adjacent sites. The Cascade Separator™ and StormFilter™ Vault system ensures compliance with environmental regulations and maintains the quality of discharge into the neighbouring creek.

This solution not only meets regulatory requirements but also provides a robust and reliable approach to managing stormwater in an industrial setting.